Product

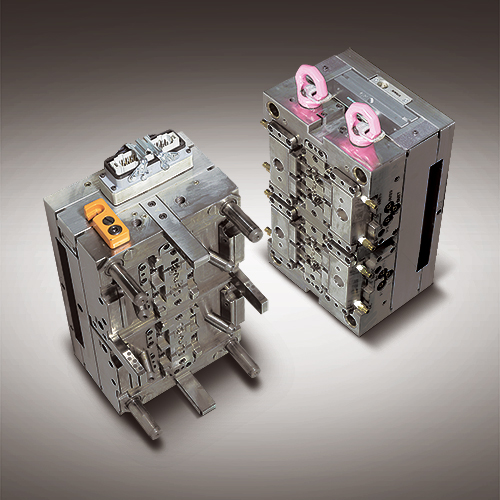

Plastic Mold

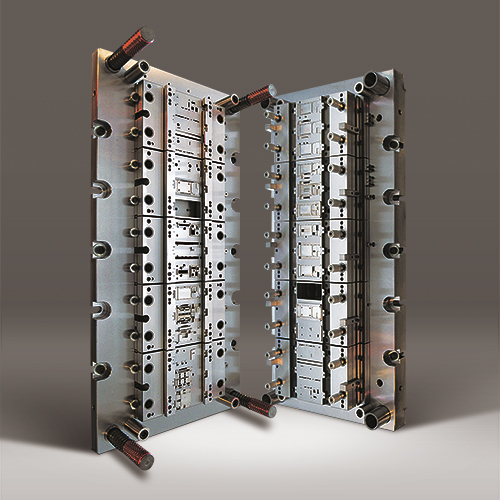

Stamping Tool

Customize Parts

Automation

Stamping tool

- Tool offset pre-measuring system that eliminates machine setup errors.

- In-house engineering department

- Scanning head CMM for inspection of mold cavities and electrodes.

- Precision grinding in a temperature controlled environment.

- In-house facilities to validate dies and moulds, and the option of producing start-up batches and serial productions.

- We work in a number of different 3D-design

Plastic / MIM Mold

- CW offer in-house design, assembly and extensive range of high end die-cutting tools and mould.

- Continue investing in the latest machines and technology to improve our speed and precision.

- Our facilities and skilled technical engineer allow us to fully maintain our tooling, as well as to produce molds for up to twenty new mold per month

CNC high-speed ultra-precision micro-machining milling

MEGA-SS600 tungsten steel drilling and tapping machining example

- Material : CARBIDE

- Hardness : 90HRA

- Dimension : 20 x 20 x 10mm

- Processing Technology :

Ø 0.4 and Ø1.0drill / M4 tapping processing - Surface roughness : Ra 0.905mm

*Use special diamond coating professional cutters(Japan)

Make Android pneumatic spindle Deep processing example

- Material : STAVAX

- Hardness : 52HRC

- Dimension : 15 x 15 x 30mm

- Processing Technology : up to 150,000/min

- Ball knife : R0.25x effective length 2.0-6.0

Compared with the general axis,the processing

time can be reduced to 90%(the groove rough process)

Android tungsten steel & steel mold nanoscale 3D type-like mirror finish

- Material : STAVAX

- Hardness : 52HRC

- Dimension : 50 x 40 x 20mm

- Surface roughness : Ra18nm (Ra0.018um)

- Realization of nanoscale 3D surface mirror polishing

- Material : ultrafine particles of tungsten steel AF-1

- Hardness : 92.5HRA

- Dimension : 10 x 10 x 20mm

- Surface roughness :

Pitch direction Ra6.8nm (Rz37.6nm)

Cutting direction Ra5.6nm (Rz26.4nm)

- Material : STAVAX

- Hardness : 52HRC

- Dimension : 70 x 50 x 30mm

- Precision modify pitch XY : 0.01mm

- Surface roughness : Ra39nm (Ra0.039um)

- Realization of nanoscale 3D shape mirror polishing

- Material: STAVAX

- Hardness: 52HRC

- Finishing: R0.2 CBN Ball endmill

- Deviation of hole size at exit side within ±3μm

- 6 areas are machined by single set up

- Significant reduction of lead time by using a 5-axis machine

- Material : STAVAX

- Hardness : HRC51

- Dimension : φ50 L=115 mm

- Processing :

rough Tool : R5.0 Ball endmill / spindle speed : 7,000min-1 / feed : 2,000mm/min

1st Tool : R4.0 Ball endmill / spindle speed : 14,000min-1 / feed : 1,000mm/min

finish Tool:R2.0 Ball endmill / spindle speed : 15,000min-1 / feed : 3,000mm/min - Machining time : 8 hours 56 minute